We know that flexible packaging that uses less material offers the same product protection as packaging made from other materials. For the applications in our markets, flexible packaging has a lower carbon footprint compared to alternative packaging materials in terms of production, logistics and disposal.

To further reduce the environmental impacts of our packaging solutions, our focus is on advanced development of our films with an emphasis on minimizing resource consumption and improving their recyclability.

Importance of Packaging

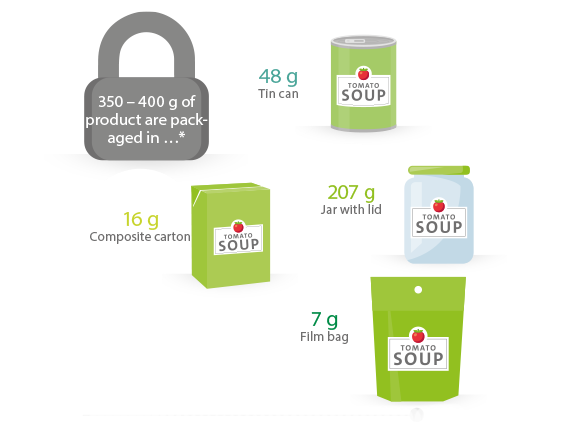

The main task performed by packaging is product protection. Packaging protects food, as well as medical goods and industrial products, from mechanical damage, contamination, light and unintentional exposure to oxygen. They help to extend the shelf life of a product and preserve its quality, thus reducing the waste of valuable resources caused by premature spoilage.

Moreover, discarded products also waste the resources that were necessary to produce the products - such as water, energy and farmland. In addition, unnecessary CO2-emissions are generated that have a negative impact on the climate.

Not least, modern packaging concepts offer the advantage of being able to conveniently, safely and hygienically store food, transport it and consume it at any time.

The need to constantly supply our global, urban and growing world population with high-quality and safe products poses major challenges for the movement of goods and, subsequently, for intelligent packaging systems as well.

High-Performance Films

Films protect food from premature spoilage, thus protecting the climate and preserving natural resources. They can also be recycled into reusable materials after use.

SÜDPACK sees itself as a cooperative supplier, seeking and systematically developing the optimal film solutions in collaboration with its customers.

To implement even the most demanding requirements, our Research & Development and state-of-the-art Application Center are available - the latter is equipped with packaging machines made by leading manufacturers, giving our customers the opportunity to perform material tests under real conditions. Innovation meetings are also held with customers here.

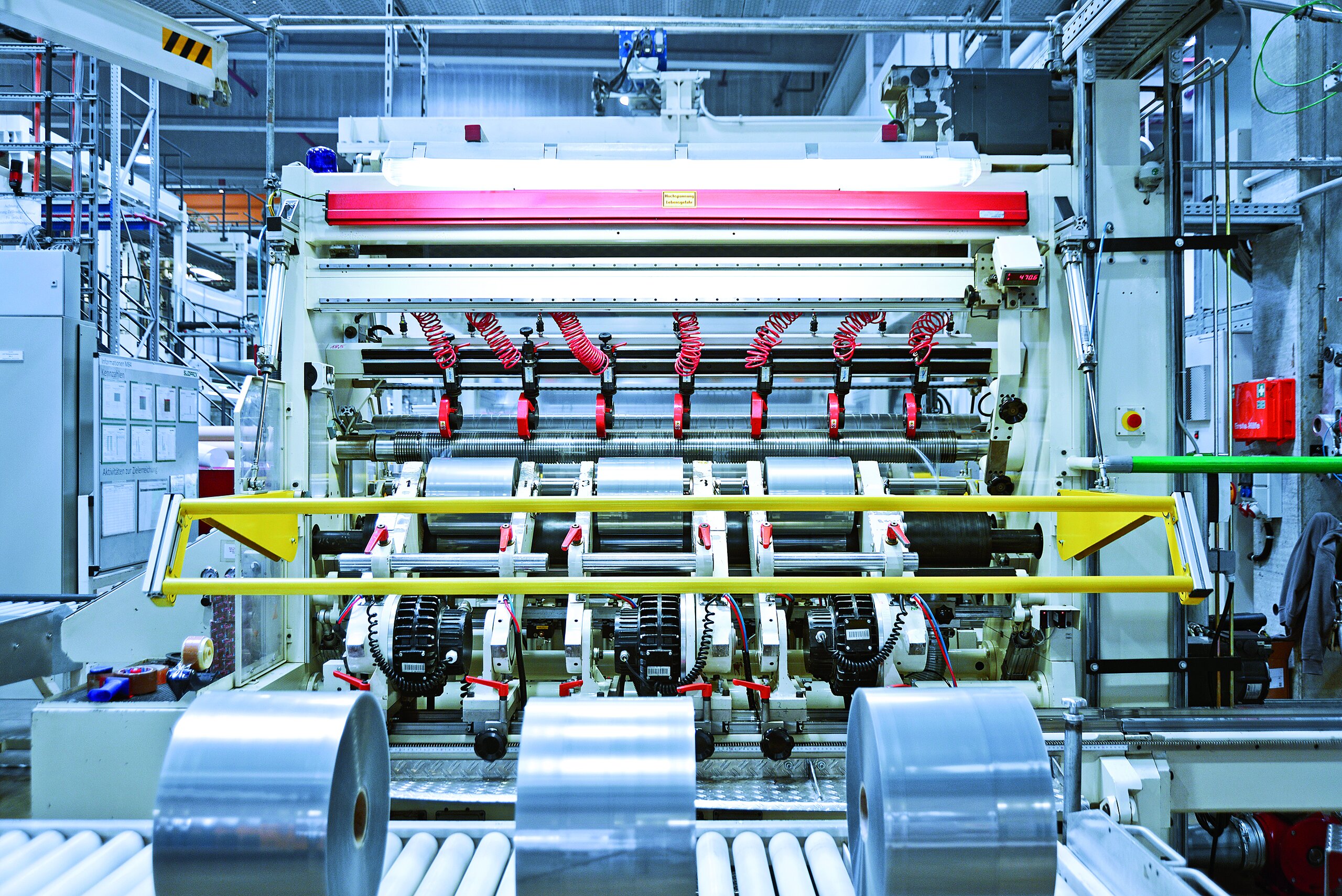

A further important contribution is made to our pace of innovation and the conservation of resources by our multiXtrusion pilot plant, which can be used for the extrusion of both blown and cast films on a small scale with up to nine layers.