Circular Economy

Closing loops. This goal is at the heart of our industry’s efforts. There is a need for more responsible handling of fossil-based raw materials across the supply chain, which is essential to optimizing our carbon footprint. In addition to the EU Plastics Strategy, which aims to implement a circular economy, the European PPWR (Packaging and Packaging Waste Regulation) is a key driver of innovation in our market. The PPWR provides guidelines for sustainable development in our industry. It identifies key action areas, such as the use of PCR (post-consumer recyclate) and the recyclability of packaging.

The circular economy has been a key component of our Sustainability Strategy for many years. Through our internal recycling efforts and our partnership with carboliq, we are making significant progress towards a circular economy.

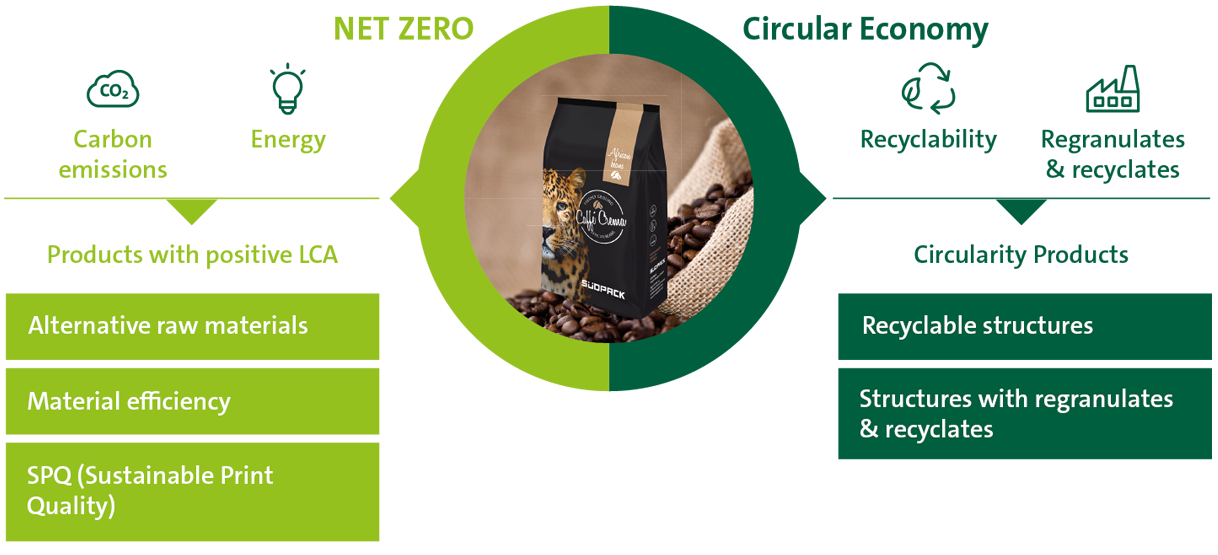

Our technological leadership is no coincidence; it is the result of our ongoing investments in new production facilities that transform production-related plastic waste into valuable recyclates, demonstrating our commitment to mechanical recycling. Additionally, we are investing in chemical recycling, a field in which carboliq plays a key role in building a functional circular economy. In accordance with our Sustainability Strategy, we aim to produce 100% recyclable products by 2030.

As a leader in innovation and technology within our industry, we are committed to laying the groundwork for a circular economy starting at the product design phase. The recyclability and recycled content of our packaging solutions are essential levers for compliance with PPWR requirements. “Sustainable product design” requires initiatives to reduce product-related CO2 emissions and advance circular film solutions. We are therefore working ambitiously on improving the overall eco-balance of our products. With an awareness of the fossil-based materials in our films, we are also prioritizing sustainable, future-ready alternatives, such as bio-based and synthetic plastics. At the same time, we are leveraging our in-house regranulation capabilities and using recyclates to drive the development of sustainable packaging solutions.

Recyclables, not waste. Through internal material management, we keep our products within the material loop, reducing both our waste volumes and disposal costs. Our overarching goal of ZERO WASTE drives our efforts in the areas of regranulation, compounding, waste reduction, and material efficiency. Our approach to material management has unlocked new possibilities for our business – especially in compounding, where our expertise allows us to offer custom, versatile solutions tailored to our customers’ needs.