Supplier management

Due to the raw material intensity of our products, our suppliers are an important part of our value chain. We are therefore extremely mindful of establishing cooperative relationships. They also form an important foundation for the implementation of product development projects. This is because the purchased materials have a significant impact on the quality of our products and on our customers' satisfaction as a result.

A team of experts is responsible for selecting suppliers at SÜDPACK and includes members with roles in Purchasing, Production, Quality Assurance, Supply Chain Management and R&D. Different criteria are taken into account, such as product quality, production processes, working and human rights practices and the suppliers' countries of origin. New suppliers are generally audited by our buyers on site before a business relationship is established.

To minimize the risk of adverse environmental effects to the greatest extent possible, we source materials that are considered critical in environmental terms, such as inks, adhesives and solvents, exclusively from Germany and Europe. About 90 % of the granules and semi-finished products come from European countries. The rest is purchased from the Middle East and from the USA and Asia.

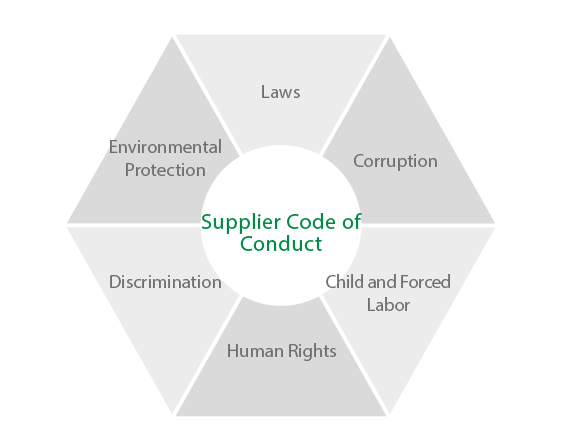

Supplier Code of Conduct

To document the fulfillment of our criteria, we developed a "Supplier Code of Practice" in 2019, which we give our suppliers for confirmation. The document includes ethical guidelines based on the principles of the UN Global Compact, the International Labour Organization (ILO) Conventions, the United Nations Universal Declaration of Human Rights, the UN conventions on the Rights of the Child and on the Elimination of All Forms of Discrimination as well as the OECD Guidelines for Multinational Enterprises.

By signing the Code of Conduct, our suppliers commit themselves to meeting their social responsibility in all business activities and to observing the applicable laws as well as any other relevant provisions in the countries where they operate in all of their commercial activities and decisions. Requirements are also defined in the Code of Conduct that concern topics such as corruption, child and forced labor, human rights, discrimination, and environmental protection. Our schedule is for all active suppliers to confirm compliance with our criteria either by signing our Code of Conduct or supplying an equivalent document by the end of 2020.

Supplier management system

The supplier management system is covered by the quality management system across the group. Within the framework of certification according to the new versions of ISO 9001 (2015) and ISO 14001 (2015), the management system was revised in 2018. ISO 50001 (2018) will be updated in April 2020.

Products from suppliers that might endanger product safety can be identified by means of a risk analysis (HACCP). lf such suppliers have not supplied certifications that are recognized by the GFSI (Global Food Safety Initiative), for instance that are in accordance with BRCGS, a supplier audit is mandatory. During the reporting period, no business relationship was put at risk due to negative effects in terms of working practices, environmental issues or human rights.

We will also continue to take steps to make lasting improvements to the supplier management system in the future. For example, the risk of a monopoly position of suppliers is to be reduced by establishing a second source. Moreover, extended talks with suppliers and audits are planned to improve quality.

Logistics

Logistics at SÜDPACK is essentially handled in close collaboration with two forwarding companies that are certified in accordance with ISO 9001 and IFS food logistics standards. Moreover, the companies are audited every two to three years. One forwarding company is responsible for the logistics of granules and raw materials, the other is responsible for purchased films, mother reels and finished products.

The new logistics center in Erolzheim reduces the internal transportation between the external warehouse and production plant by approximately 50%.

,,Zero Pellet Loss"

One thing is clear: Plastics are a valuable material and do not belong in the environment. For this reason, SÜDPACK has been involved in the "Zero Pellet Loss" initiative of the German Association for Plastics Packaging and Films since 2016. This initiative aims to prevent plastic granules from entering the environment or sewage system, where they can subsequently contaminate coastal areas and seas.

This has led SÜDPACK to take extensive measures in production to further minimize granule loss. Process steps that are particularly critical include the filling of silos and further transport of the granules within the production process. lt is imperative here to prevent granules from being spilled and to immediately sweep up and carefully dispose of spilled granules.