LEAN Management

An important element of our corporate governance is lean management.

We consider lean management an important concept that provides standardized methods and tools, which allow us to continue working with a focus on customers and goals and thus maintain profitable growth. Lean management was already implemented at SÜDPACK prior to this reporting period. It is now being successfully applied across the entire SÜDPACK Group and continuously developed as an essential cultural building block.

The management system provides standardized mindsets, methods and tools that help define common goals for the company group and raise each employee’s awareness of the contributions they can make to reach our goals.

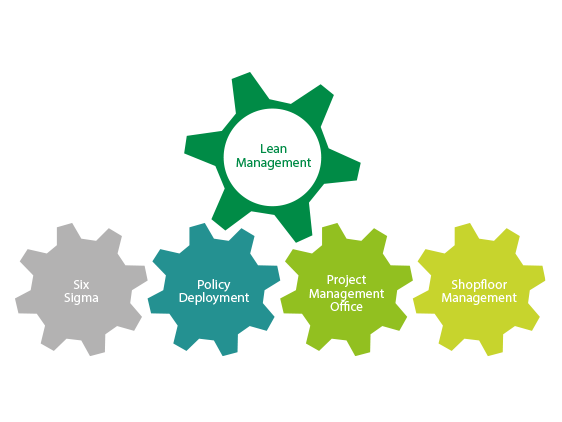

Leading LEAN tools, which interlock at SÜDPACK.

One area of focus is the development of smooth and waste-free processes to minimize real problems that occur on the path to achieving the defined objectives. The aim of lean management is to make processes leaner and reduce unnecessary work steps, which in turn makes cooperative work more efficient and ultimately more customer-oriented along the entire value chain.

The execution of lean management culture is lived by the Management Board and carried on in all areas and on all levels of hierarchy.

The defined goal is for every individual employee to understand and actively use the management system in their daily work.

Leading lean tools that are used at SÜDPACK include policy deployment, shopfloor management, PMO (project management office) and Six Sigma.

Shopfloor Management

Shopfloor management has already been established across the group in almost all production and administrative departments. By using shopfloor management, goals that are relevant to a department and essential for achieving corporate goals are visualized and measured to develop necessary measures and proactively manage teams. Employees are shown the extent to which their work contributes to reaching the goals of the company so they can perform daily tasks in the most targeted manner possible. The results are compared in regular meetings. Problems are examined and discussions are held about progress in finding solutions and support needed from senior management.

Cross-departmental meetings also provide an opportunity to investigate flow problems with upstream and downstream processes and to define strategies to overcome them. This makes it possible to map out an internal customer-supplier relationship that is one of close cooperation, resulting in a positive approach to error management. If employees are not able to solve the identified problems on their own, projects are launched to find solutions and an objective is formulated for the up-stream process.

The meaning of lean management is also explored in more depth in the different departments in regular on-site meetings with Company Management. At the same time, Company Management conducts active shopfloor management.

PMO (Project Management Office)

The most significant projects that emerge from shopfloor management can be found in our project management tool PMO. Almost every department now has its own PMO board, where all projects are clearly displayed. On the PMO boards, all of the projects are classified and the contribution they make to reaching corporate goals and the resources available for them are prioritized using a stage-gate process.

Six Sigma

An additional key element of the lean management culture at SÜDPACK is Six Sigma. Six Sigma takes a structured approach to process improvement for problems that keep employees from reaching their goals. This approach makes it possible to analyze and process complex issues using statistical tools. SÜDPACK has worked intensely on training Six Sigma experts over the last two years and now has a wealth of expertise in the field.

During this reporting period, a total of 22 employees completed Six Sigma training. In 2018, an employee won the silver German Six Sigma Award of the European Six Sigma Club Deutschland e.V. In the year that followed, the Deutsche Six Sigma Preis Praxis was awarded to a SÜDPACK employee for the best practical application of Six Sigma methodology.

We intend to continue to increase the number of experts in the years to come and to incorporate the Six Sigma method into the company to an even greater extent.

Because the lean management system only functions as a holistic approach, SÜDPACK has made the implementation of the lean management methods policy deployment, shopfloor management, PMO and Six Sigma a priority for the years to come. In addition to further expansion of lean management in production, a particular focus will be on enhancing shopfloor management and PMO boards in further commercial areas such as Sales and Internal Sales.