Raw material consumption

For SÜDPACK, reducing the consumption of raw materials and closing reusable material loops are of primary importance. By doing so, we too are making a significant contribution to the implementation of the 2018 Plastics Strategy of the European Union.

Raw material consumption

We were able, for example, to reduce our use of materials in all product segments. Already in 2012,

we set standards in terms of downgauging with the market launch of our Veraplex World product family. This is because, compared to conventional film composites, Veraplex offers improved performance with a material savings of to 50 %.

Reduction of granulate consumption

*Please refer to the Progress Report 2021 for current figures.

The impact of our activities regarding material reduction are demonstrated by the optimization of the ratio between film area and weight. While the area of film produced in 2019 increased by 21.6 % compared to 2017, a much lower amount of materials was used with an increase of just 9.12 %.

In addition to reducing film thickness, we also see potential for optimization in laminating adhesive. By implementing further measures, it was possible to reduce the total adhesive usage in the second step by increasing the amount of solvent-free laminating, which meant less adhesive was applied. Total adhesive usage in 2019 was 12 % less than in the same period of the previous year. Further measures to reduce the amount of adhesive are planned for the years to come, provided that they are technically feasible and permitted by our customers’ application conditions. Alongside economic advantages, it is possible here – most particularly with solvent-free laminating – to create massively positive environmental effects (reduction of residual solvents and VOC emissions).

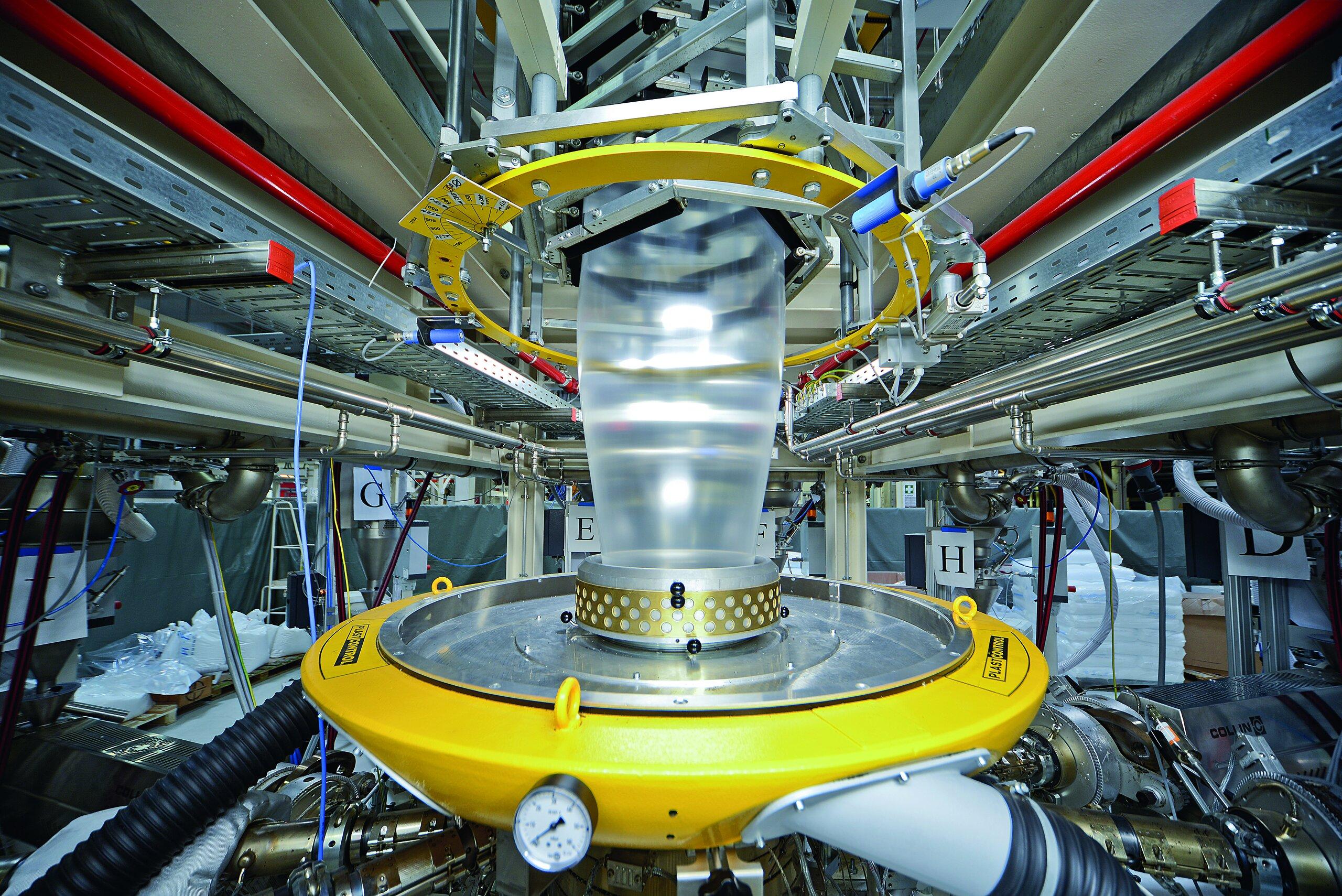

Saving resources - "multiXtrusion"

Not least, an important contribution to our pace of innovation and resource conservation has been made by our investment in the "multiXtrusion" pilot plant, which can be used to extrude both blown and cast films on a small scale. With this pilot plant, which we primarily use to complete tests, small orders and customer samples, we have been able to significantly reduce both the amount of waste that is normally generated in the production of small volumes as well as energy consumption. The "multiXtrusion" plant has also had a positive impact on our industrial facilities, whose efficiency has also increased.

Closing material loops

In addition to reducing raw material consumption, we are continuously working on closing reusable material loops. The use of recyclate from post-consumer material decreases the share of newly produced, fossil-based raw materials. To ensure consistent quality and food safety standards, we only work with EFSA-listed and certified recycling companies.

Additionally, inline scrap and start-up material is regranulated wherever possible and incorporated in our co-extruded composites. At our Competence Center, we are working intensely on the regranulation and compounding of granules.

In the new plant in Erolzheim, a system has been established for sorted collection of edge pieces for even better control of material flows. This makes it possible to manufacture high-quality regranulate. Moreover, the investment in inline regranulation equipment made it possible to increase the direct reuse of inline scrap in 2019 by more than 25 % compared to the previous year. To work in the most eco-friendly manner possible and avoid unnecessary transportation routes, our aspiration for 2020 is to process the residual materials from the production of rigid film, which we currently hand over to third parties for regranulation, ourselves.